How to Select the Right RIB® Relay for HVAC Applications

So you’ve decided to go with a Functional Devices’ RIB relay for your HVAC system. Congratulations! But the hurdle remains: RIB relay selection. Which model do you choose? The options can seem overwhelming. Don’t stress; we’re here to help!

The pre-wired and pre-assembled design of Functional Devices’ RIB relays makes them a popular choice for all sorts of industries and applications, including commercial HVAC systems. Their convenience, reliability, and versatility are unparalleled in the market. Whether you’re a seasoned HVAC professional or new to the trade, utilize this HVAC RIB relay guide to choose the correct relay for your specific application.

Here at Functional Devices, we’ve been perfecting relay designs since 1969. We stand behind our products 100 percent and test each one before it leaves our production floor. You can have peace of mind that you're purchasing a relay we’ve treated with the utmost care. We also stand behind our customer service. If you have any questions or concerns, don’t hesitate to contact us!

Learn the Basics of Functional Devices’ RIB® Relay

The first step in choosing a RIB relay for HVAC is to learn the basic function of relays in HVAC systems and how we categorize our relays.

What Do Relays Do in an HVAC System?

As with most types of commercial controls, a relay in an HVAC system provides a bridge between differing voltages among associated equipment. This is especially important in HVAC where low-voltage components like thermostats must manage high-voltage components including compressors, air handlers, and fans. A relay ensures safe and reliable operation and interaction between critical equipment.

Quick RIB Relay Guide

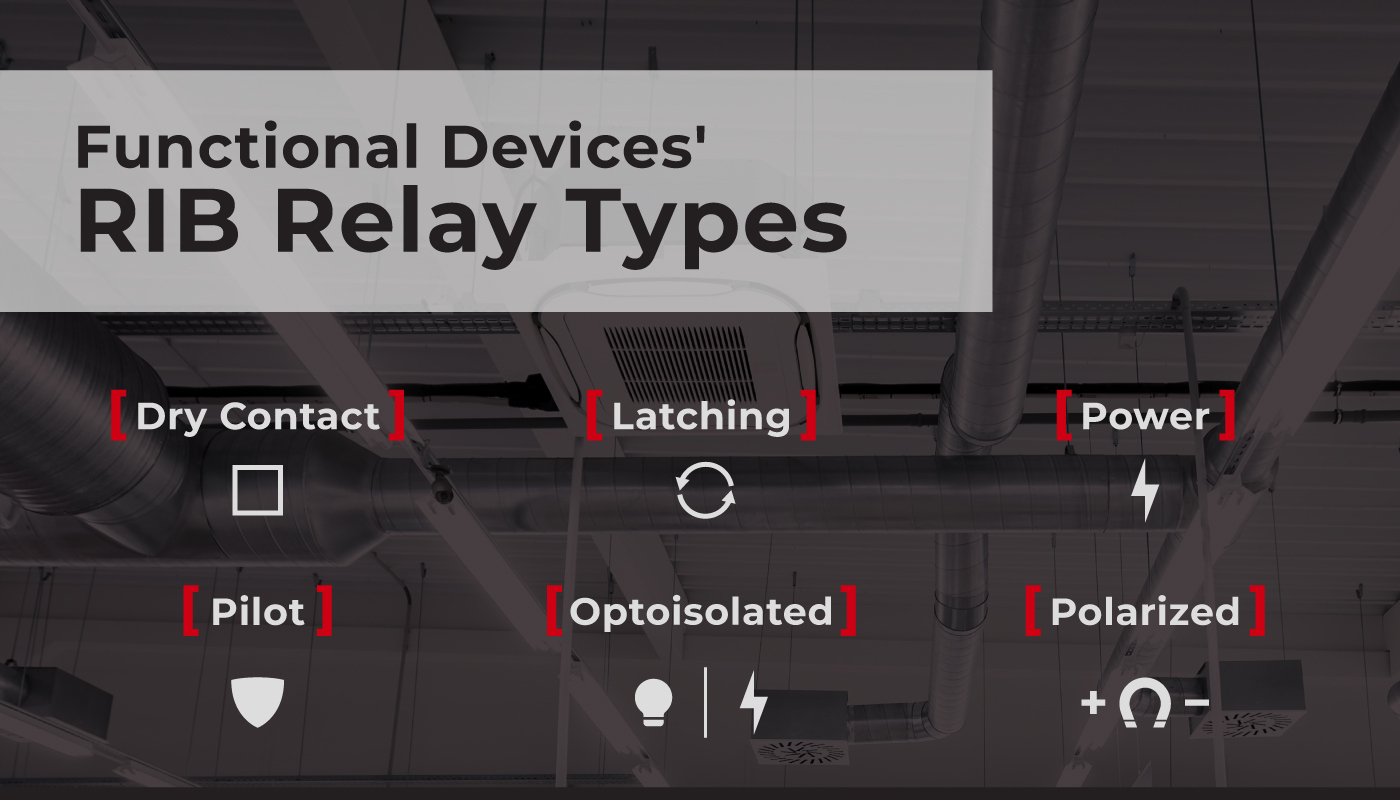

Functional Devices’ RIB relay types include:

- Dry contact input. Have a unique control input, which can detect the change in state of a separate dry contact opening or closure. The status of the dry contact dictates the state of the relay output.

- Latching. Maintains contact position even after the power source is removed. Only needs a small pulse to switch position. Good for emergency situations.

- Optoisolated. Extremely low current draw on the control signal input, which widens the use cases of reliable mechanical relay devices.

- Pilot. Low-power option that manages control signals between a control circuit and a larger relay or contactor responsible for switching a high-voltage load. Good for protecting sensitive control equipment.

- Polarized. Used in applications such as fire alarm supervisory circuits because of polarized DC voltage input. Require a specific polarity for control signal to operate.

- Power. Handle higher current and may be used to switch larger electrical loads. Robust ratings could allow for avoiding the use of a definite purpose contactor.

You could easily use all six different types of RIB relays in your HVAC system. With all the various equipment, load requirements, and designs inherent in HVAC, there isn’t one certain type that works and others that don’t. So, we need to dive deeper!

Identify Control Voltage & Load Requirements

Now you know broadly the different types of RIB relays. The next step in picking the right RIB relay for HVAC is to know what you need for your unique system. What’s the control voltage you’re working with? How about the type and size of load? These questions need to be answered before you can select the best model for the job.

Control Voltage

If you don’t match control voltage correctly, at best, your HVAC system won’t work as efficiently as it could. At worst, you’ll compromise the safety of occupants and risk damaging expensive equipment. Common control voltages in HVAC include 24Vac, 120Vac, and 208-277Vac.

You can identify the control voltage in one of two locations: the thermostat or the transformer’s secondary terminals. Measure the voltage between the red (R) and common (C) wires using a multimeter set to AC voltage. The coil rating of the relay you choose needs to match the control voltage.

Load Requirements

There are different types of loads—resistive, inductive, and capacitive—which a relay in an HVAC system must manage. Resistive loads include heating elements like electric furnaces. Inductive loads include motor loads such as fans, compressors, and air pumps. Capacitive (also known as Electronic Ballast) loads grow more popular as facilities adopt Electrically Commutated Motors (ECMs), as well as any other product that converts AC voltage into DC voltage. LED lighting is an example of this load type.

To determine load requirements, check amperage ratings that are stated on the datasheets, nameplates, or any other documents that are associated with the load to be controlled by the relay. After knowing the load requirements, you need to select an RIB relay with a contact rating that is greater than or equal to the rating of the load.

Consider Mounting & Space Constraints

Where will you be installing your RIB relay? This is another question to answer in your quest for the best model. You can mount relays in a variety of locations and sometimes, you won’t have a lot of space. That’s why we offer several different mounting options, including:

- Surface or panel mount

- Snap-track

- DIN rail

- Threaded hub (for conduit or knock-out connections)

With these options, you can basically install an RIB relay wherever you need it. If you have any flexibility for where you mount your RIB relay, choose a location based on accessibility for installation and maintenance.

Look for Additional Features That Fit Your Application

The next step in RIB relay selection is to answer: are there other features that are important to you? Here are some options we offer and might enhance the efficiency and functionality of your HVAC system. Features include:

- Time delay options for sequencing or preventing short cycling

- Current sensing capabilities for automated load detection

- Enclosure ratings (NEMA-rated cases for indoor/outdoor use)

- Built-in indicator lights for troubleshooting

We design our RIB relays for ease of use, not only during installation but for the whole life of the device. Capitalizing on these convenient features will upgrade your HVAC system to the next level of efficiency, safety, and longevity.

Verify Code Compliance and Manufacturer Specs

We craft RIB relays with attention to code, and it’s still a good idea to verify that the relay you select meets local electrical codes. You can find relevant information in our datasheets, and if you have any questions, contact the manufacturer or your local building authority.

Additionally, you can look for Underwriters Laboratories (UL) or Canadian Standards Association (CSA) certifications, which will be a good sign the relay will meet code. These designations mean you’re buying a safe and reliable product.

Cheat Sheet: Choosing an RIB® Relay for HVAC Made Easy

Many of our RIB relays will work for HVAC applications. Here are some of our most popular models and their applications.

|

Application |

Control Voltage |

Load Type |

Recommended RIB Models |

Key Features |

|

Light duty fan or blower control |

24 VAC |

Inductive (motor) |

RIBU1C |

Universal coil (10–30 VAC/VDC or 120 VAC), SPDT contacts, Various HP motor load options |

|

Pump control |

120 VAC |

Inductive |

RIB2401B |

20A contacts, pilot duty rated, NEMA 1 enclosure |

|

Compressor lockout |

24 VAC |

Inductive |

RIBU2C |

Two SPDT relays in one enclosure, dual control |

|

Lighting control (HVAC-linked) |

208–277 VAC |

Electronic Ballast/Fluorescent |

RIB2421B |

20A rated, heavy-duty contacts, LED indicator |

|

Staging or short-cycle prevention |

24 VAC |

Various |

RIBTD2401B |

Adjustable time delay (6 sec - 20 min), SPDT |

Load ratings should always be verified against the actual HVAC system specs before installation.

Get Help with RIB® Relay Selection

We hope this RIB relay guide has gotten the cogs turning. We recommend reaching out to us to discuss your system’s requirements and help you verify the right RIB relay for HVAC, making sure you’ve taken into account all the main selection factors: voltage, load, mounting, features, and compliance.

Choosing an RIB relay for HVAC improves efficiency, safety, and the lifespan of equipment. We look forward to assisting you with RIB relay selection, so please reach out to connect with our engineers. They would be happy to walk you through your options!