Do you need low voltage power at multiple locations across a job site? You have options — but some are more efficient than others. Before you start running high voltage to every location, it’s worth considering smarter solutions that save time, money, and hassle.

The Traditional Approach: Complicated and Costly

One option is to run high voltage to each location, install a transformer at each point, add circuit protection, and put in a switch. But running high voltage all over a site can get expensive fast. Another approach is to centralize your high voltage, build a custom low voltage power distribution panel, and wire everything to that single point. Sounds efficient — until you factor in the need for multiple transformers, terminal strips, primary and secondary circuit protection, switches, indicators, a convenience outlet, UL approval, and separation for high and low voltage areas. That’s a lot of work, cost, and time — with plenty of room for error during setup.

There’s a Better Way With Functional Devices, Inc.

As my dad says, “Shirley, there’s another way.” Functional Devices, Inc., offers pre-built, reliable low voltage power distribution solutions that simplify installation and cut troubleshooting time. With everything you need in one ready-to-go panel, you can get power where you need it faster, safer, and more cost-effectively — all while meeting code requirements and keeping your inspector happy.

Everything You Need With RIB®

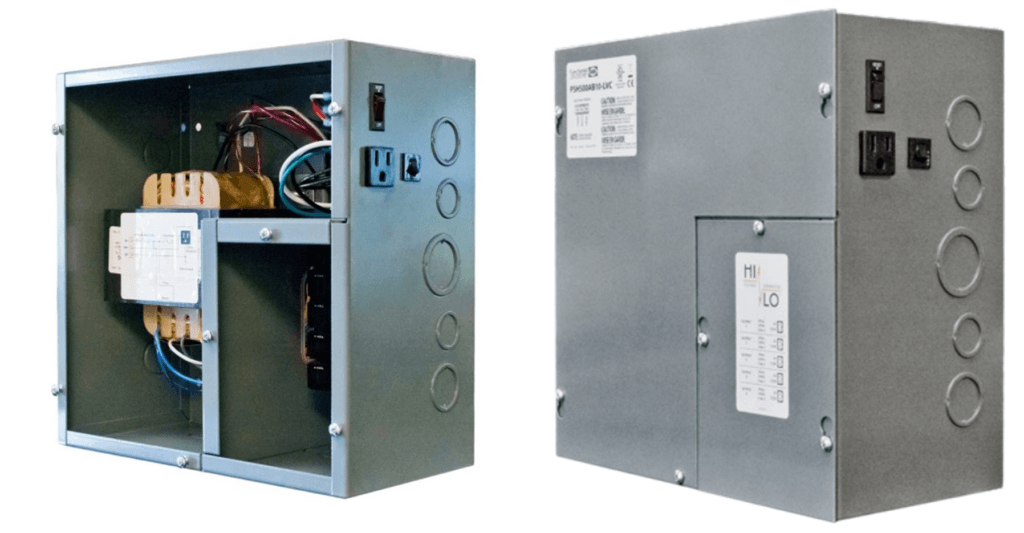

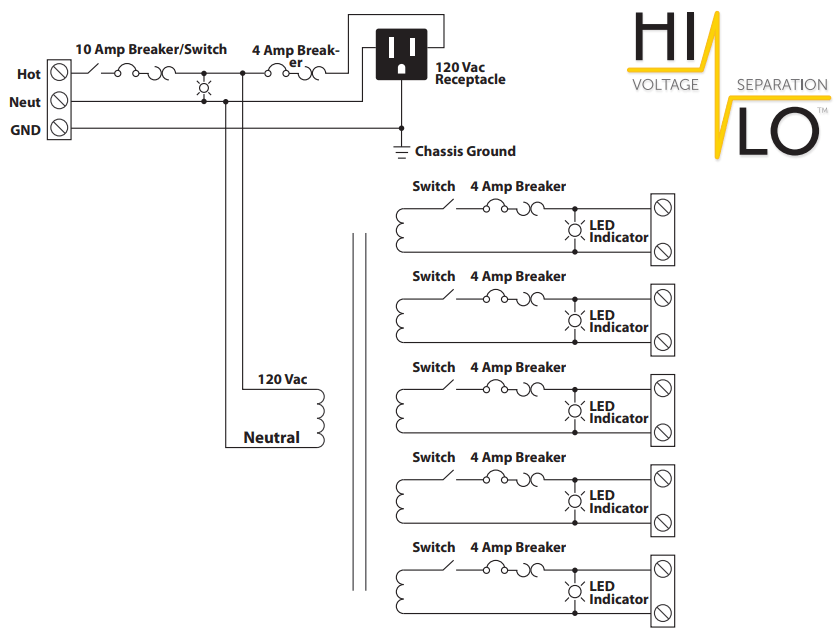

The image above shows our PSH500AB10-LVC. The main breaker/switch is located on the outside. Directly below it is a convenience outlet with its own 4 Amp breaker. There is a two-piece lid. One covers the high voltage side of the supply and the other allows access to the low voltage circuits. Each of the secondary circuits are isolated from one another. They have their own 4 Amp circuit breaker, an ON/OFF switch, LED indicator, and pluggable terminal. The diagram below shows the internal connections of PSH500AB10-LVC.

One of the notable features of these supplies is the low voltage compartment (LVC). It provides Hi/Lo voltage separation for safety. All the secondary circuits in the supplies are Class 2 low voltage. Having the compartment to separate these connections from the high voltage means a technician can access the circuits for commissioning or troubleshooting in a safe and cost-effective manner. The secondary LED indicators aid in troubleshooting and the ON/OFF switches allow for maintenance of downstream loads. We also offer versions of these power supplies without all the bells and whistles and offer advantages over a one-off solution.

These UL-listed, distributed, low-voltage power supplies can allow anyone to standardize on a versatile solution to save time and money on their next control job. Why go with the Do-It-Yourself approach each time you spec a project? Give your installers and technicians what they want, a simple, consistent, straightforward power solution they can trust. That is why we say that Functional Devices, Inc. offers "Confidence & Peace of Mind in Every Box."

About Functional Devices, Inc.

Confidence and Peace of Mind in Every Box

At Functional Devices, Inc., we have been designing and manufacturing high-quality electronic components in the USA since 1969. Our mission is simple: to enhance lives in buildings and beyond by delivering reliable, innovative solutions for the building automation industry. Our product lineup includes RIB® relays, current sensors, power controls, power supplies, transformers, lighting controls, and more—each designed to meet the highest industry standards.

We test 100% of our assembled products, ensuring an exceptionally low failure rate—less than 1 in 16,000 in the field. This commitment to excellence means you get products that perform reliably, reducing downtime and increasing efficiency. With every Functional Devices product, you receive more than just a component—you gain confidence and peace of mind knowing your systems are built on trusted, field-proven technology.