Traditional 3-way or 4-way switch wiring often requires running large, high-voltage conductors over long distances, adding cost, complexity, and the need for conduit. Dry contact relays can offer a smarter alternative, using low-voltage control wiring to achieve the same switching functionality with fewer materials and easier installation.

Functional Devices has been designing and manufacturing innovative electrical control solutions in the U.S. for decades. Known for our reliable RIB® relays, current sensors, and building automation products, we help contractors and facility managers streamline installations, save money, and meet code requirements. Explore our line of dry contact RIB relays today.

In this blog, you’ll learn how RIB dry contact relays work, why they’re ideal for multi-switch applications over long distances, and how they can dramatically reduce installation costs while improving flexibility.

How Dry Contact Relays Work

A dry contact relay is essentially an electrically operated switch that keeps the control circuit completely isolated from the load circuit. When a small control signal is applied to the relay’s coil, it activates an internal switch (the “dry contact”) that can open or close a separate circuit. This allows low-voltage wiring to safely control higher-voltage or higher-current equipment without direct electrical connection between the two circuits.

Because the control wiring only needs to carry a very small current, contractors can use smaller-gauge wire over longer distances without worrying about excessive voltage drop or costly conduit. The load circuit remains safely isolated, making the installation not only less expensive but also more flexible and easier to maintain.

By using dry contact relays in applications such as multi-way switching, building automation, or remote equipment control, you can streamline wiring layouts, cut installation costs, and maintain safe operation for both control and load systems.

3-Way Switch with Dry Contact Relays

Now let’s dive into some wiring specifics and hypotheticals with our dry contact relays.

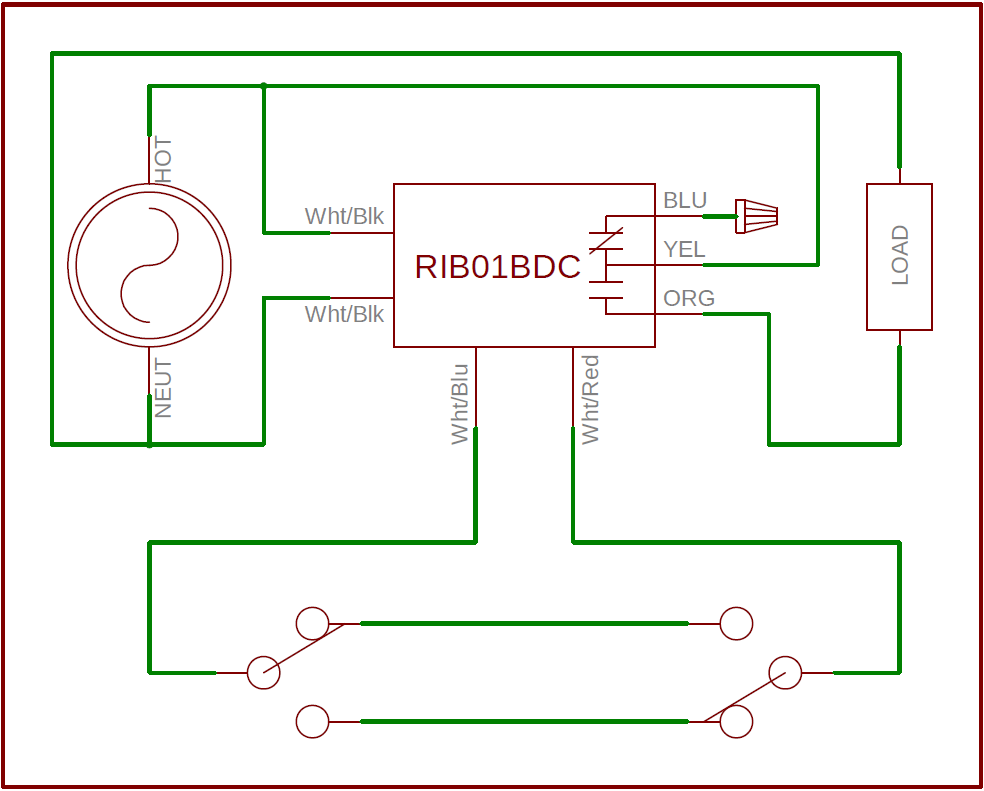

The diagram above shows one of our dry contact relays, RIB01BDC, wired with two SPDT switches. This achieves a 3-way switch application. The relay could be installed at the load location and would be powered by the same voltage as the load. The RIB01BDC must be powered by 120 Vac, so this relay would be used with a 120 Vac load. If the load were 208-277 Vac, the RIBD02BDC could be used.

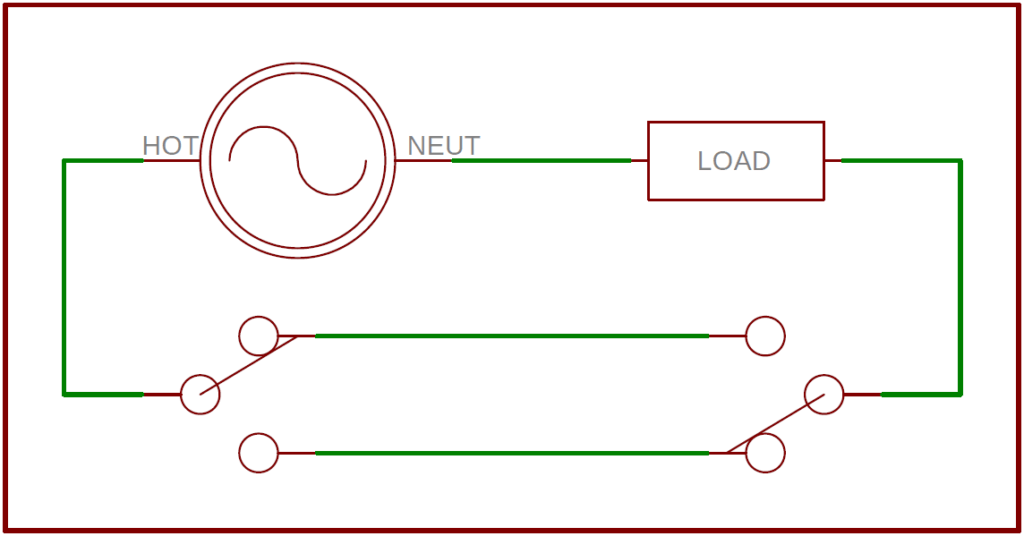

In the typical 3-way switch application, shown below, the Hot feed is fed through both switches to get to the load. In the application with the relay, shown above, the two switches are connecting the Dry Contact Input wires on the RIB01BDC. When these two wires connect, the Normally Open (N/O) relay contact will close, and the load will be powered.

Typical 3-Way Switch

The real benefit of using the Dry Contact relay is that the Dry Contact Input (Wht/Red and Wht/Blu wires) is low voltage and Class 2 rated. That means the connection between the two switches does not have the same code requirements as those in the second diagram. The Dry Contact Input only passes microamps of current. Therefore, the length of wire between the two switches can be very long.

For the relay to actuate, there needs to be less than one megaohm of resistance between the Dry Contact Input wires. That means someone using 18AWG wire could place their switches about 150,000,000 feet apart — roughly 28,400 miles.

For perspective, that’s farther than a trip around the Earth (24,901 miles), so in theory the switches could be so far apart they’d meet up again on the other side! While no one’s likely running a control circuit around the globe, the point stands: dry contact relays let you run control wiring very, very far without the cost or code headaches of high-voltage conductors.

Technical FAQs About Dry Contact Relays

Q: What is the maximum contact rating on the load side of a dry contact relay?

A: While the control side carries only microamps, the load side can typically switch line-voltage circuits. For RIB dry contact relays, this can range up to 20A at 277 VAC (check individual datasheets for exact ratings).

Q: How does contact material affect relay performance?

A: Most dry contact relays use silver alloy contacts with special surface treatments to minimize arcing and pitting. This increases contact life and ensures stable performance with inductive loads such as ballasts, motors, or transformers.

Q: What is the dielectric isolation between the control circuit and load circuit?

A: RIB dry contact relays typically provide several thousand volts of dielectric isolation between the coil (control side) and the load contacts, protecting low-voltage controls from transients or faults on the line side.

Q: Can dry contact relays handle DC loads?

A: Yes, but DC switching characteristics differ from AC. Always consult the relay’s DC ratings; switching inductive DC loads may require snubbers or arc suppression for maximum contact life.

Q: How fast can a dry contact relay respond?

A: Relay operation times are usually in the 10–20 ms range with similar release times. This makes them suitable for most control and automation applications but not high-frequency switching.

Save Money with Functional Devices

Dry contact relays aren’t just convenient; they’re engineered for robust performance in demanding control environments. Their isolated contacts allow safe interfacing between low-voltage control systems and high-voltage loads while maintaining high dielectric strength and long contact life. By understanding ratings such as contact material, isolation voltage, and switching characteristics, engineers and installers can take full advantage of these devices to create safer, more efficient, and longer-lasting systems.

For detailed specifications and trouble shooting, always consult the product datasheet or reach out to Functional Devices’ technical support team. And when you’re ready to upgrade your projects with reliable, field-proven relays, choose Functional Devices for the performance and support you can trust.

About Functional Devices, Inc.

Functional Devices, Inc., located in the United States of America, has been designing and manufacturing quality electronic devices since 1969. Our mission is to enhance lives in buildings and beyond. We do so by designing and manufacturing reliable, high-quality products for the building automation industry. Our suite of product offerings include RIB relays, current sensors, power controls, power supplies, transformers, lighting controls, and more.

We test 100% of our products, which leads to less than 1 out of every 16,000 products experiencing a failure in the field.

Simply put, we provide users of our various products confidence and peace of mind in every box.