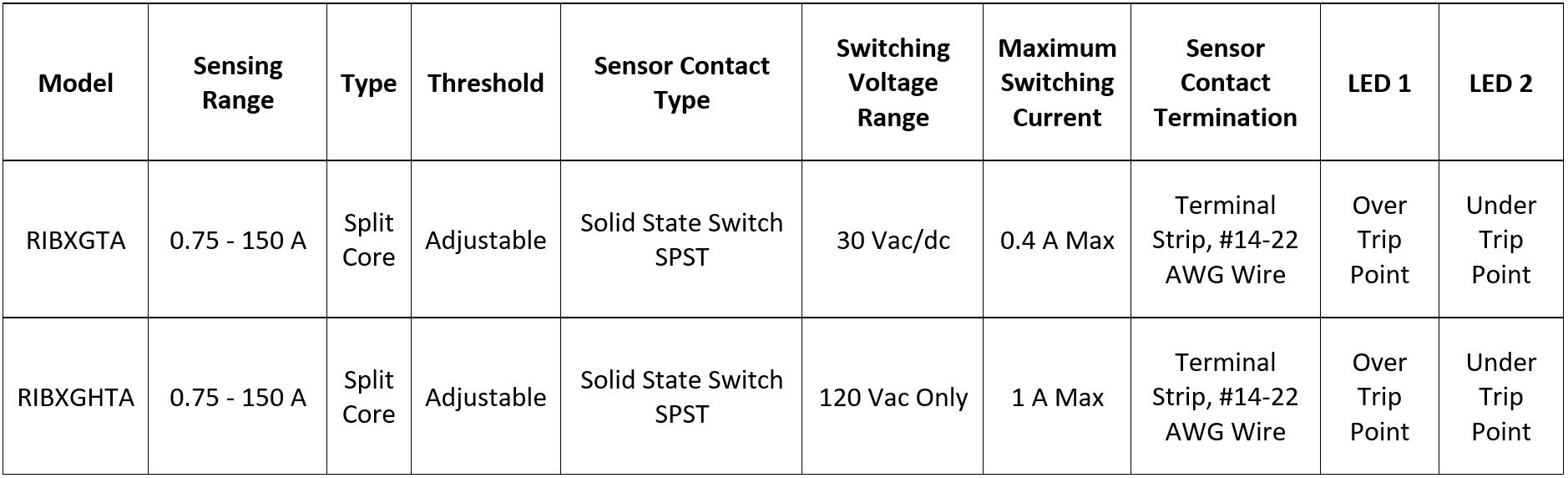

Selecting the Correct Current Sensor: RIBXG Series vs. RIBXGH Series

Looking at the table above, we can see that both models have a sensing range of 0.75 - 150 A, are split cores, and adjustable thresholds. The key difference is in the contact ratings and what those contacts do with and without a load.

A common application for our current sensors is to interface to a building automation system (BAS) to know if certain loads are on or off. This is typically done via a dry-contact closure, and the RIBXGTA is an excellent choice. Model RIBXGHTA however would not work as expected.

Once the load current being monitored exceeds the threshold, the RIBXGTA will close its contacts and function perfectly as a dry-contact output for the BAS.

Model RIBXGHTA would also close its contacts, but without a load would measure approximately 250 ohms. This resistance causes the BAS to not register the dry-contact closure, giving a false indication that the load is off. This resistance is normal though, as the RIBXGHTA was designed to control 120 Vac loads.

If you have an application requiring a current sensor, take a look at what we offer. As always, if you have any questions or need help selecting the right product, be sure to contact us.

About Functional Devices, Inc.

Functional Devices, Inc., located in the United States of America, has been designing and manufacturing quality electronic devices since 1969. Our mission is to enhance lives in buildings and beyond. We do so by designing and manufacturing reliable, high-quality products for the building automation industry. Our suite of product offerings include RIB relays, current sensors, power controls, power supplies, transformers, lighting controls, and more.

We test 100% of our products, which leads to less than 1 out of every 16,000 products experiencing a failure in the field.

Simply put, we provide users of our various products confidence and peace of mind in every box.